2-HEAD FILLING MACHINE

Volumetric filling system.

Designed for liquid, semi-liquid, viscous, and solid products.

Capacity: 840 – 1600 units/hour.

Filling accuracy: ± 1%.

Anti-drip filling nozzles.

Compatible with various packaging sizes and shapes.

Capable of both hot and cold filling.

Compliant with food hygiene standards.

Detail

Capacity for double-head filling machines varies according to the following filling ranges:

| Model | Filling Range | Capacity (units/hour) | Operating Mode |

| PVD200-2 OTPAY / PDD200-2 OTPAY | Min. 5 – Max. 200 ml | 1600 | Pneumatic |

| PVD1000-2 OTPAY / PDD1000-2 OTPAY | Min. 100 – Max. 1000 ml | 1500 | Pneumatic |

| PVD2000-2 OTPAY / PDD2000-2 OTPAY | Min. 200 – Max. 2000 ml | 1200 | Pneumatic |

| PVD5000-2 OTPAY / PDD5000-2 OTPAY | Min. 1000 – Max. 5000 ml | 840 | Pneumatic |

Technical Specifications:

Draws product from an 80-liter hopper equipped with an automatic level control system.

The level control system is synchronized with a transfer pump for automatic starting or stopping.

All components, including valves and nozzles, are connected with tri-clamps for easy disassembly during cleaning.

Dosage adjustment is easily set and recorded via a handwheel and a digital counter.

Features interchangeable filling nozzles with an anti-drip system designed for liquid and viscous products.

Includes an adjustable diving nozzle system for foamy products.

Touchscreen interface available in multiple languages.

Includes a 2-meter conveyor with adjustable side guides to accommodate various packaging sizes.

The operating system is pneumatic and electronic, requiring 6 bar compressed air.

Air consumption is 600 L/min when operating at maximum volume and speed.

Electrical connection is three-phase (380V / 50-60 Hz).

Optional Features: CIP-compatible cleaning system, double-jacketed hopper, internal stirrer system, and a flushing system for the rear of the filling pistons.

Materials Used:

Durable chassis constructed entirely from stainless steel and anodized aluminum.

FESTO brand pneumatic equipment (oil-free system).

OMRON PLC, touchscreen, and drives.

Sick sensors.

Operating Temperature:

Filling can be performed from 5 ºC to 85 ºC with standard seals, and above 90 ºC with special material gaskets.

Filling Accuracy: ± 1%

Fillable Products:

Food & Dairy: Chocolate Cream, Nut Butters, Honey, Mayonnaise, Ketchup, Mustard, Sauces, Jam, Tomato/Pepper Paste, Cream Cheese, Labneh, Yogurt, Milk, Ayran, Kefir, Molasses, Vinegar, Syrups, Pomegranate Sour, Edible Oils, Ready Meals, Appetizers, Russian Salad, Purees, Olive Paste, Pastry Jellies, Soups, Cake Batters, etc.

Cosmetics: Cosmetic Oils and Creams, Shampoo, Conditioner, Liquid Soap, Shower Gel, Body Lotion, Masks, Wax, Gels, Vaseline, Foundation, BB Cream, etc.

Pharmaceutical & Medical: Ointments, Lotions, Glycerin, Disinfectants, Biomedical and Sanitary Products, Veterinary Products, etc.

Chemicals: Paints, Glue (PVA), Hydrogen Peroxide, Ink, Fertilizers, Pesticides, Varnish, Household Cleaners, Engine Oil, Glass Cleaner, Antifreeze, etc.

Optional joints

Optional Filling Piston

Used to enable the filling of products in volumes smaller than the standard capacity of the existing filling machine by replacing the piston and cylinder assembly.

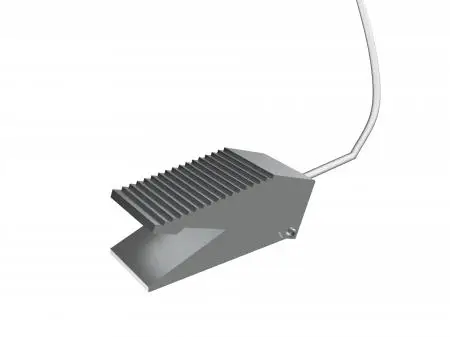

Foot Pedal

Stirrer

Used to ensure the homogeneous mixing of particulate products or to maintain consistent temperature and texture for heated products during the filling process.

Double-Walled Hopper

Used for products requiring hot filling or to facilitate the flow of high-viscosity products by heating them to the desired filling temperature prior to the dosing process.

Piston Rear Washing System

Used for filling sticky products to ensure the piston operates more reliably and to extend the service life of the seals.

Level Detection System

Used for cases where the product is transferred into the hopper via a transfer pump or when the product level within the hopper needs to be monitored, this sensor-equipped hopper lid ensures automated level control.

Dense and Particulate Product Filling Nozzle

Used to fill dense and particulate products into various types of packaging or directly onto products with the help of a flexible hose.

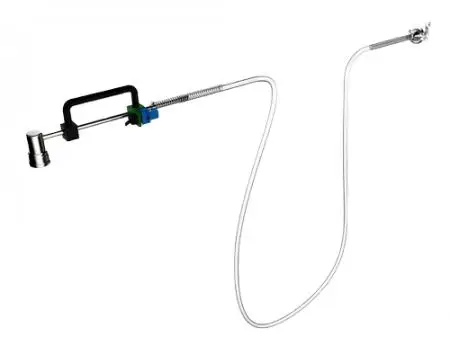

Injection Nozzle

Used primarily in pastry products (such as eclairs and muffins) to inject cream or similar fillings directly into the product.

Spouted Doypack Packaging Filling Nozzle

Used for filling products into Doypack (stand-up pouch) packaging.

SN01 Filling Nozzle

This nozzle is used for filling products with volumes up to 150 ml.

Dairy Product Filling Nozzle

Used for filling dairy products such as clotted cream, strained yogurt, and yogurt with cream into various types of packaging.

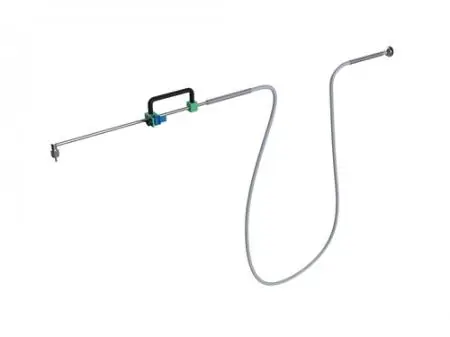

Yeast (Rennet) Filling Nozzle for the Dairy Industry

This is a specialized filling nozzle with a flexible hose, specifically designed for dosing yeast (starter culture) in the dairy industry.