D5000 FILLING MACHINE

NUMBER OF FILLING CYLINDERS ON THE MACHINE: 1

FILLING RANGE: Min. 500 ml – Max. 5000 ml

OPTIONAL FILLING PISTON: Min. 145 ml – Max. 1450 ml

CAPACITY: 420 containers / hour

Detail

MACHINE FEATURES:

The machine is a volumetric filling machine operating with a pneumatic system.

Weight adjustment is easily performed and recorded via a handwheel and a counter.

It automatically draws the product to be filled directly from the production tank.

High surface smoothness and argon welding technology prevent bacterial growth and contamination.

Sealing elements are manufactured from Teflon, Viton, or Polyethylene materials, depending on the chemical properties and temperature of the product to be filled.

Parts on the machine are connected to each other with tri-clamp connections.

The nozzle, valve, and filling piston are designed for easy cleaning and can be easily disassembled without using any tools.

Interchangeable filling nozzles are available for liquid, viscous, or granular products.

There is a platform with a drawer to place containers during the filling process; this platform can be easily adjusted up and down according to the height of the packaging.

The machine stands on a stainless steel frame supported by 4 wheels. Thanks to its wheels, it can be easily and quickly made ready for filling in the desired location.

Benchtop and mobile (wheeled) models are available.

The machine operates with 6 bar pressurized air; no electrical or electronic systems are used in the machine.

Detailed user manuals are available for each model.

MATERIALS USED IN THE MACHINE:

All surfaces in contact with the product are made of 316L grade stainless steel. Other external surfaces, guard plates, and legs are made of 304 grade stainless steel and aluminum.

FESTO brand pneumatic equipment (oil-free system).

OPERATING TEMPERATURE: Filling can be performed from 5°C to 85°C with standard seals, and above 90°C with seals made of special materials.

FILLING ACCURACY: ±1%

PRODUCTS SUITABLE FOR FILLING: Honey, Tahini, Molasses, Liquid Sauces, Olive Oil, Pomegranate Syrup, Vinegar, Turnip Juice, Milk, Ayran, Kefir, Boza, Fruit Juice, etc.

Optional joints

Spouted Doypack Packaging Filling Nozzle

Used for filling products into Doypack packaging.

SN065 Filling Nozzle

This nozzle is specifically used for dripping products such as chocolate cream and honey.

SN02 Filling Nozzle

This nozzle is used for filling liquid and viscous products in volumes exceeding 100 ml.

Rear Piston Flushing System

Used for filling sticky products to ensure the piston operates more reliably and to extend the service life of the seals.

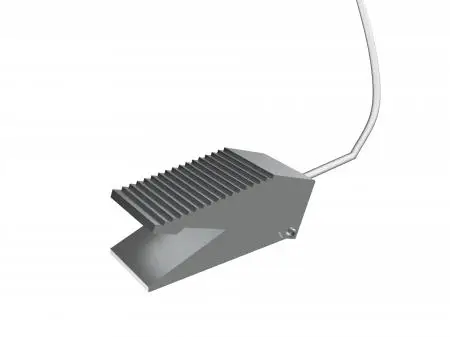

Foot Pedal

Optional Filling Piston

Used to enable the filling of product volumes smaller than the standard capacity of the existing filling machine.