2-HEAD FILLING MONOBLOCK

FILLING AND CAPPING MACHINE ON THE SAME CHASSIS FOR LIQUID,

4-HEAD FILLING MONOBLOCK

FILLING AND CAPPING MACHINE ON THE SAME CHASSIS FOR LIQUID,

6-HEAD FILLING MONOBLOCK

FILLING AND CAPPING MACHINE ON THE SAME CHASSIS FOR LIQUID,

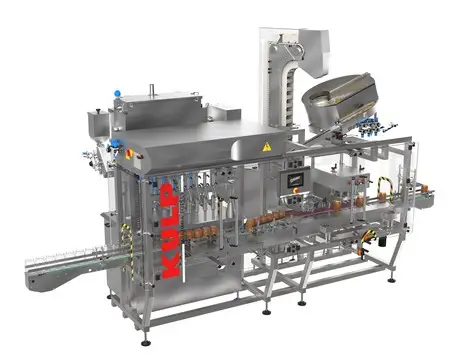

Monoblock Filling Machines

Monoblock Filling Machines: Giant Production and Compact Power in Tight Spaces

In today’s world, where factory rents and square-meter costs are rising, utilizing a production facility efficiently is no longer a choice—it is a necessity. Consider the chaos and loss of space created by massive conveyors and meters of different machine tracks trying to connect to one another. Have you ever thought, “I wish a single machine could handle all these operations”?

This is exactly where Monoblock Filling Machines were born: out of that very need.

At Kulp Makine, we define these systems as the “Swiss Army Knife” of the production world. These machines perform filling, capping, and sometimes even labeling on a single chassis like a synchronized dance, saving you space while taking your operational efficiency to its peak.

Let’s take a closer look at these compact giants, which are the favorites of the pharmaceutical, cosmetic, and food sectors.

What is Monoblock? Why “All-in-One”?

In traditional lines, the filling machine is separate, followed by 2 meters of conveyor, and then the capping machine. This takes up space and increases the risk of bottles toppling, becoming contaminated, or jamming while moving from one machine to another.

In monoblock systems, the logic is: “Grip the bottle once and don’t let go until the job is done.” The empty bottle enters a rotating star wheel. As this star wheel rotates, the following steps happen in sequence:

Station 1: The bottle is cleaned (with air).

Station 2: Filling is performed.

Station 3: The cap (and dropper/plug, if applicable) is placed.

Station 4: The cap is tightened.

All of this happens in a single rotation without the bottle ever leaving the machine.

The Big Hero for Small Bottles

Monoblock machines can be produced in any size, but they show their greatest strength with small-volume bottles prone to toppling. Think about it: transporting a 10 ml eye drop, a 30 ml e-liquid bottle, or hotel-sized mini shampoos on a conveyor is difficult. They are light; they can fall over with a mere puff of air.

In a monoblock system, the bottle is “locked” into the slots of the star wheel, so it does not shake or topple. Even a 5 ml liquid bottle can be filled and capped at speeds of thousands per hour with millimetric precision. If you have a low-dosage, multi-part product (bottle + dropper + cap), the solution is definitely Monoblock.

Kulp Makine Difference: The Pinnacle of Hygiene and Precision

Monoblock machines are generally used in areas where hygiene is critical, such as pharmaceuticals (eye drops, syrups, nasal sprays) and cosmetics (perfume samples, serums).

With this awareness, we at Kulp Makine keep our standards at the highest level:

1. 316L Stainless Steel and GMP Compliance

All surfaces of our machines that come into contact with the product are manufactured from indisputable 316L grade stainless steel. The body design complies with Good Manufacturing Practices (GMP) rules; meaning there are no indentations that hold dust or dead spots that are difficult to clean.

2. A One-Person Powerhouse

You do not need dozens of staff to manage a monoblock machine. A single operator can stand at the machine to control empty bottle feeding, fill the cap hopper, and monitor the finished products. Our touch-screen HMI panel allows you to manage the entire process from a single point.

3. Flexible “Star” Design

You might wonder, “I’m producing 30 ml today, but what happens if I switch to 50 ml next year?” Changing formats in monoblock machines is not as difficult as it seems. You can switch to a different bottle simply by changing the star wheel that holds the bottle and the related molds—a process that is very practical with Kulp machines.

Advantages List: Why Should You Invest?

If you are still wondering if separate machines would be better, take a look at these advantages:

Minimum Space: It solves the work of 3-4 different machines in an area of approximately 2-3 square meters. It gives your factory room to breathe.

Energy Savings: A single main motor and drive system operates all units. Instead of the electricity consumption of 3 separate machines, you lower costs with the consumption of just one.

No Synchronization Issues: There is no worry about the filling machine being fast while the capping machine stays slow. Since they all rotate with the same gear system, they are in perfect harmony.

Maximum Hygiene: Operations take place inside a closed cabin (glass enclosure). Contact with the outside environment is minimal. Optionally, a HEPA filter can be integrated into this cabin to create a sterile atmosphere.

Monoblock as an Engineering Art

As Kulp Makine engineers, we work with the precision of a watchmaker when designing Monoblock systems. Every detail communicates with the next, from the silence of the cap feeding unit (vibrator) to the non-drip performance of the filling nozzle.

These machines end the chaos on your production line and replace it with peaceful order. Your operator doesn’t run around in a panic; they simply monitor the system. Your products leave the line standardized, clean, and safe.

Conclusion: The Production Model of the Future

Efficiency, speed, and space savings… this is the holy trinity of modern production. Monoblock filling and capping machines offer all three in a single body.

If you produce sensitive, small-volume, and high-value-added products such as pharmaceuticals, dermocosmetics, e-liquids, or food supplements, Monoblock technology is not a luxury—it is a necessity for staying competitive.

Meet Kulp Makine’s local production power, fast service support, and tailor-made design capability. Let’s plan together how we can create wonders in your limited production space.

Frequently Asked Questions (FAQ)

1. Can different bottle shapes (e.g., square and round) work on the same monoblock machine?

Yes, they can, but the star wheel and some carrier parts must be changed. Round bottles are the easiest for monoblocks. For square or oval bottles, we use specially designed stars because “orientation” is required. Specifying all bottle types you will use when ordering the machine allows us to design accordingly.

2. What is the speed of a monoblock machine?

Speed varies according to the product’s viscosity, the weight, and the number of stations (number of filling heads) in the machine. A single-nozzle monoblock can produce 1,500-2,000 units per hour, while in multi-station rotary systems, this speed can reach 6,000-10,000 units per hour.

3. Can it insert droppers, plugs, or safety seals in addition to the cap?

Absolutely! This is the biggest advantage of monoblock machines. It can perform operations in sequence: Filling -> Dropper Insertion -> Cap Placement -> Cap Tightening. A labeling unit can even be integrated at the end.

4. How long does cleaning and part replacement take?

Kulp Makine designs are based on a Tool-Free changeover logic. Switching from one format to another takes between 20-40 minutes, depending on the operator’s experience. Options compatible with automatic washing (CIP) systems are also available.

5. Do these machines only fill liquids? Can they fill cream?

Yes, they can. By integrating piston filling units, you can successfully fill and cap viscous products such as lotions, creams, and gels in a Monoblock system.