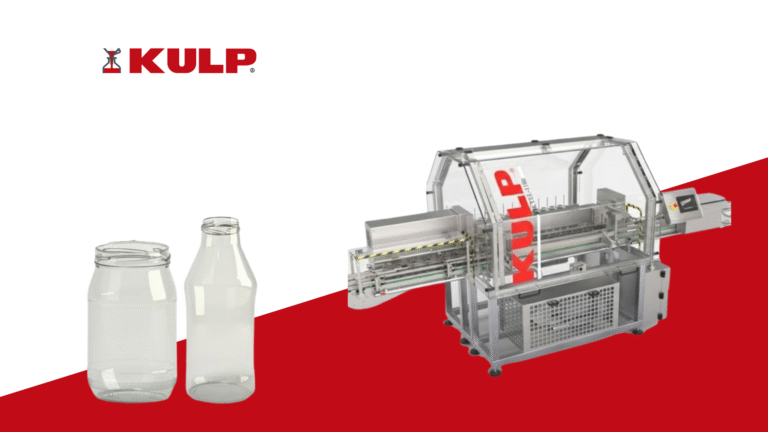

The KULP automatic filling line is a versatile solution designed to handle a wide range of liquids, including vinegar and balsamic vinegar. This system is engineered to provide a seamless, high-speed packaging process from start to finish.

Anti-Foaming and Precision Filling To eliminate the risk of foaming or product overflow, the system utilizes a specialized bottom-up filling technique. The filling nozzles descend to the base of the container and gradually rise toward the neck during the filling process. This movement is controlled by servo motors, ensuring high-precision filling levels and consistent performance for every bottle.

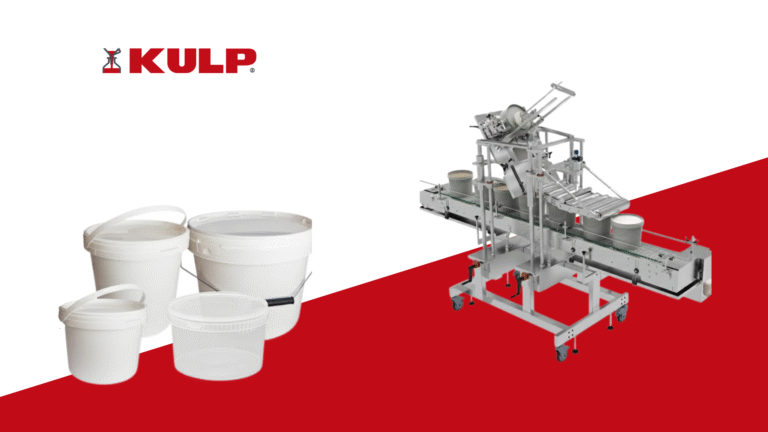

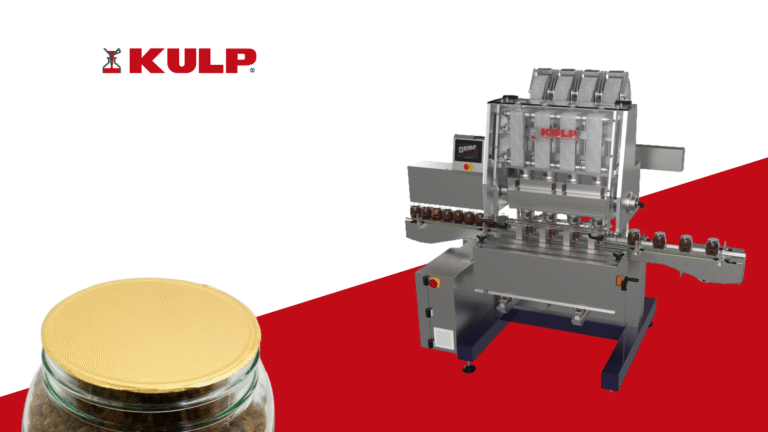

Automated Capping and Finishing Once the filling cycle is complete, the containers move automatically to the capping station. Here, caps are fed onto the bottles and secured without manual intervention. This ensures a hygienic and efficient transition to the final stage of the line.

Labeling and Shipment Preparation Following the capping process, the filled plastic bottles undergo wrap-around labeling, giving the product a professional and market-ready appearance. Finally, the bottles are gathered on a collection tray at the end of the line, organized and ready for final packaging and shipment.