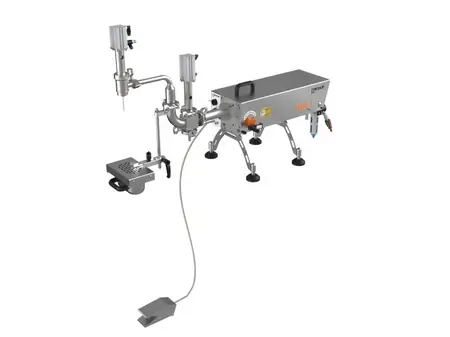

Semi-Automatic Filling Machine provides the perfect answer for medium and small-scale production needs. Produced to the highest standards using food and pharmaceutical grade 316L stainless steel, this machine is ideal for a wide variety of filling applications. Semi-Automatic Machines built for benchtop operation by a single operator who manually places a container under the filling nozzle. Simple to use, easy to clean, requires low maintenance.

VD50 FILLING MACHINE

Number of filling cylinders in the machine: 1 Filling range:

VD150 FILLING MACHINE

Number of filling cylinders in the machine: 1 Filling range:

VD200 FILLING MACHINE

Number of filling cylinders in the machine: 1 Filling range:

VD500 FILLING MACHINE

Number of filling cylinders in the machine: 1 Filling range:

VD1000 FILLING MACHINE

Number of filling cylinders in the machine: 1 Filling range:

VD2000 FILLING MACHINE

Number of filling cylinders in the machine: 1 Filling range:

VD5000 FILLING MACHINE

MAKİNADAKİ DOLUM SİLİNDİRİ SAYISI: 1 DOLUM ARALIĞI: Min. 500 ml

Consistent Product Filling Machines

Viscous Product Filling Machines: The Formula for Speed and Precision in Challenging Fluids

In the world of production, there is a simple truth: the more “precious” your product is, the more challenging its filling process becomes. Honey, tahini, peanut butter, thick moisturizing creams, or industrial greases… The common characteristic of these products is their stubborn texture that defies gravity. If you are reading these lines, you likely have a wonderful product, but you want to end the sticky nightmare, the stress of hitting the right weight, and the waste of time you experience while filling it into jars or bottles.

Let’s be honest; filling a product that flows like water is easy. The real mastery lies in transferring that thick, viscous product—which barely even pours from a spoon—into the packaging in seconds, gram for gram, and without making a mess. This is exactly what Viscous Product Filling Machines are designed for: these “tough missions.”

As Kulp Makine, we have worked with thousands of products of varying densities, from honey to cosmetics, over the years. We have seen that when the right technology is not used, the filling process becomes the biggest bottleneck of the business. So, how do you overcome this bottleneck?

What Do We Mean by “Viscous Product”?

To someone outside the industry, “liquid is liquid,” but for us manufacturers, the situation is very different. Viscosity—the resistance of a fluid to flow—changes everything in machine selection.

Products whose fluidity changes with temperature (Honey, chocolate cream).

Products containing particles (Jam, chunky sauces).

Thick gels prone to foaming (Shampoo, shower gel).

Products with a spreadable consistency (Hummus, face masks).

If you are filling manually or using the wrong machine, product stringing (trailing behind like a thread), nozzle dripping, or inconsistent weights are inevitable. This is not just a waste of time; it is also a serious waste of product.

Why Won’t an Ordinary Filling Machine Work for You?

Standard “gravity filler” machines you see on the market are great for thin products like water or juice. However, if you put a thick cream or tahini into such a machine, you would wait hours for it to flow.

Viscous products require power. That is why the systems designed by Kulp Makine for viscous products utilize Piston Volumetric Filling technology. Think of this as a giant, high-precision syringe made of stainless steel. The machine draws the product into the cylinder with a strong vacuum and then pushes it into the packaging with high (but controlled) pressure. The result? Even the most stubborn pastes find their place in the jar within seconds and at the exact desired weight.

Kulp Makine Difference: 3 Golden Rules of Trouble-Free Filling

It is easy to get lost in technical tables when making a machine investment. However, there are three vital features you must pay attention to regarding thick products. We have established these three rules as “must-haves” when designing our machines:

1. Anti-Drip and Anti-Stringing Nozzle System

What is the biggest fear of those filling honey or tahini? That “last drop” hanging from the tip of the nozzle after filling is finished. That drop smears onto the edge of the bottle, ruins the label, and makes the cap sticky. Our machines feature special “shut-off” systems that close the nozzle tip the moment the product flow stops. The filling ends, and the flow is cut like a knife. Your bottle stays clean and moves safely to the labeling machine.

2. Hygiene at Food and Pharmaceutical Standards (316L Stainless Steel)

Viscous products are more susceptible to bacterial growth or leaving residues between machine parts. Therefore, there can be no compromise on material quality. We use 316L Stainless Steel on all surfaces of our machines that come into contact with the product. Why 316L instead of 304? Because 316L is much more resistant to acidic products (such as lemon sauces or certain chemicals) and corrosion. Even as years pass, your machine will not rust and will not spoil the taste or structure of your product.

3. Easy Cleaning and Part Replacement

The biggest headache with thick products is cleaning. If you are filling strawberry jam in the morning and cherry jam in the afternoon, cleaning the machine should not take hours. In Kulp Makine designs, we use “Tri-Clamp” connections that can be disassembled without the need for tools. Your operator can remove and wash the piston, nozzle, and hoses within minutes. Production does not stop, and your workflow is not interrupted.

Which Industries Are These Machines Ideal For?

Viscous product filling machines actually have a much wider range of use than you might think. Here are the areas where our consultants use these machines most:

Food Industry: Honey, molasses, tahini, peanut/hazelnut butter, mayonnaise, ketchup, mustard, pomegranate syrup, jam (with or without chunks), spreadable chocolate, yogurt, hummus.

Cosmetics and Personal Care: Face masks, clay masks, hair conditioners, petroleum jelly, wax, toothpaste, thick body lotions.

Chemistry and Industry: Grease oil, silicone, paste adhesives, paint, ceramic glazes.

Semi-Automatic or Fully Automatic Filling Solutions?

This question depends entirely on your production volume.

Semi-Automatic Machines: Perfect for entry and mid-level needs. An operator places the jar, presses the pedal, and the machine fills. If you are doing between 3,000 and 5,000 fills per day, it is both budget-friendly and compact.

Fully Automatic Lines: If your daily production reaches tens of thousands, you can switch to our conveyorized lines where filling, as well as capping and labeling, are done untouched by human hands.

But remember; whether semi-automatic or fully automatic, the heart of the filling technology (the piston and nozzle structure) maintains the same quality standards.

A Piece of Advice from One Producer to Another

Sometimes you might think, “I could fill this with a funnel too, why do I need a machine?” However, when you want to grow your business, you must standardize. Think of a customer in a market; if they see stickiness on the lid of a honey jar or a visible level difference between two jars, their trust in that product is shaken.

A viscous product filling machine does not just gain you speed; it provides your brand with a professional image. Your customer knows they are buying a product of the same quality, the same fullness, and perfectly clean every single time.

Conclusion: Overcome Challenges with Technology

Producing thick viscous products is hard, but packaging them doesn’t have to be. With the right equipment, you can turn those “non-flowing” stubborn products into the fastest stage of your production line.

As Kulp Makine, we stand by you with our high-precision, non-drip machines produced with 316L quality. No matter how thick your product is, we certainly have a machine that speaks its language. Come visit our factory with your product or send us a sample. Let’s test the most suitable machine for you together and see the results with your own eyes.

Frequently Asked Questions (FAQ)

1. Can I fill my jam with fruit particles using this machine?

Yes, you definitely can. Thanks to the special “rotary valve” systems and wide nozzle tips we use, we can transfer fruit pieces in jam or vegetable pieces in sauce into the jar without crushing them or spoiling their form.

2. I need to perform hot filling (e.g., 85°C), is the machine suitable for this?

Many products must be filled hot for food safety. All seals and contact surfaces in our machines are selected from materials resistant to high temperatures (Viton, PTFE, etc.). You can safely fill at temperatures like 85-90°C.

3. My product is very solid (e.g., paste), can the machine pull it?

Yes. Our piston systems have a strong suction power. Additionally, for very solid products, we can add a “heated hopper with a stirrer” onto the machine. This way, the product is softened inside the hopper, making its flow into the machine easier.

4. What is the weight precision? Will I lose money due to overfilling?

Since our machines work volumetrically, the margin of error is very low (usually ±1%). For example, in a 500-gram jar, it works with deviations so small they cannot be noticed by eye. This protects your pocket by preventing raw material waste.

5. Can I fill jars of different sizes with the same machine?

Certainly. You can easily change the volume (for example, from 100cc to 1000cc) using the adjustment handle on the machine. The height of the filling nozzle can also be adjusted for different jar heights. You can package multiple types of products with a single machine.