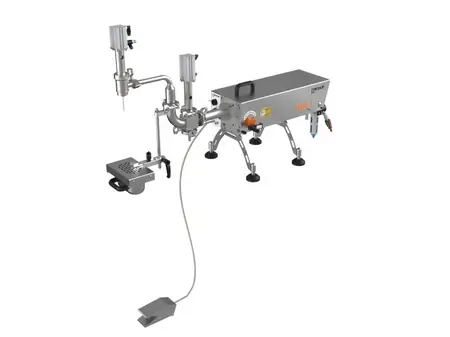

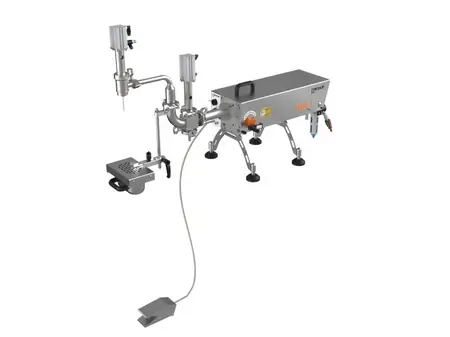

Semi-Automatic Filling Machine provides the perfect answer for medium and small-scale production needs. Produced to the highest standards using food and pharmaceutical grade 316L stainless steel, this machine is ideal for a wide variety of filling applications. Semi-Automatic Machines built for benchtop operation by a single operator who manually places a container under the filling nozzle. Simple to use, easy to clean, requires low maintenance.

D50 FILLING MACHINE

NUMBER OF FILLING CYLINDERS IN THE MACHINE: 1 FILLING RANGE:

D150 FILLING MACHINE

NUMBER OF FILLING CYLINDERS IN THE MACHINE: 1 FILLING RANGE:

D500 FILLING MACHINE

Number of filling cylinders in the machine: 1 Filling range:

D1000 FILLING MACHINE

NUMBER OF FILLING CYLINDERS IN THE MACHINE: 1 FILLING RANGE:

D5000 FILLING MACHINE

NUMBER OF FILLING CYLINDERS ON THE MACHINE: 1 FILLING RANGE:

Liquid Product Filling Machine

Liquid Filling Machines: The Silent Heroes of Your Production Line and the Ultimate Selection Guide

In the world of manufacturing, especially if you are in the “kitchen” of the business, you know exactly how fast time flies. On one hand, there is the rush to meet orders, and on the other, the struggle to never compromise on product quality. Perhaps as you read this, you are thinking about how to most efficiently fill bottles or jars with that wonderful product of yours—be it a food sauce or a specialized cosmetic cream.

Let’s be honest: as your production volume increases, manual filling becomes not only exhausting but also a costly mistake. This is exactly where liquid filling machines come into play. However, these machines are not just “piles of metal”; they are the most loyal business partners in your company’s growth journey.

With the years of experience we have gained at Kulp Machine, we can say that choosing the right machine is not just about saving the day—it is an investment in the future. So, which one is the right choice for you among thousands of options? Let’s sit down and discuss this seemingly complex topic together, just like a friendly coffee chat.

What is Liquid Filling and Why is it So Critical?

The process seems simple: take a liquid and put it in a container. But when weight precision, hygiene standards, and speed come into play, the situation changes. Liquid filling machines are systems that transfer your products—regardless of their flowability (from water to honey, shampoo to olive oil)—into packaging in pre-determined amounts without error.

Many manufacturers prefer manual methods when they first start. Filling with funnels, adjusting by eye… these methods may seem “economical” at first. However, every drop of product spilled is actually a piece of your profit gone. Not to mention the hygiene risks.

A professional filling machine offers you:

Standardization: You offer every customer the exact same product, down to the milligram.

Speed: You condense work that takes hours by hand into minutes.

Hygiene: You perform filling through closed systems without human contact.

Semi-Automatic Filling Machines: Why Are They Ideal for SMEs?

Not everyone needs a massive factory or fully automatic lines. In fact, sometimes fully automatic systems can be bulky and unnecessarily expensive for boutique producers. This is where Semi-Automatic Filling Machines take the stage.

We call this the “tabletop revolution.” Why? Because these machines operate under operator control, but the machine handles the most critical part of the process: filling at the correct weight. A single operator places the container under the filling nozzle, presses the pedal, and the machine works its magic.

The Kulp Machine Difference: The 316L Stainless Steel Miracle

You might get lost in the list of technical specifications when buying a machine. However, the most vital detail you should pay attention to is material quality. At Kulp Machine, we use 316L Food and Pharmaceutical Grade Stainless Steel in our semi-automatic filling machines.

Why is this important? Ordinary stainless steels can lose resistance over time against acidic products (such as lemon juice or certain chemicals). However, 316L is extra resistant to corrosion. This means you can fill honey today, and after cleaning, fill an acidic cleaning material tomorrow. Your products won’t have a metallic taste, your machine won’t rust, and it will maintain its first-day brightness for years. Frankly, if you are in the food or pharmaceutical sector, 316L is not a preference; it is a necessity.

Which Industries Are They Suitable For?

Sometimes our consultants come to us worrying, “I wonder if my product will fill in this machine?” Our answer is usually a resounding “Yes.” The flexibility of semi-automatic systems makes them usable across a very wide spectrum.

Food Sector: Honey, tahini-molasses, jam, sauces, olive oil, fruit juices… For any business wanting to produce in accordance with food regulations, these machines take center stage in the kitchen. Being able to perform precise filling even with thick (high viscosity) products is a huge advantage.

Cosmetics and Personal Care: Shampoo, liquid soap, cream, lotion, acetone… Cosmetic products are valuable. Even one gram of waste affects costs. Additionally, packaging cleanliness is very important in cosmetics; thanks to machine filling, the trouble of overflowing or smudging on bottles ends.

Chemicals and Pharmaceuticals: Disinfectants, syrups, cleaning gels… There is no margin for error in these sectors. Semi-automatic machines bring laboratory precision to the production floor.

Ease of Use and Operational Efficiency

Technology can sometimes be intimidating. Questions like “What if I can’t use it?” or “What if it breaks and I can’t fix it?” might be on your mind. You are absolutely right. Complex panels and incomprehensible buttons slow down production.

That is why at Kulp Machine, our philosophy is based on the principle “Simplicity is the ultimate sophistication.” Our semi-automatic filling machines:

Are Simple to Use: Your operator doesn’t need to be an engineer. Anyone can use the machine safely with short training.

Are Easy to Clean: The biggest nightmare in food and pharmaceutical production is cross-contamination. Our machines can be cleaned and ready for the next product in minutes, thanks to easy-to-disassemble parts (like tri-clamp connections).

Require Low Maintenance: A robust structure, few moving parts, and high-quality components… This formula provides an experience that will make you forget the frequency of “calling for service.”

Filling Machine as an Investment Decision

Looking only at the current price tag when buying a machine can be misleading. Think of it this way: you have a staff member who fills 500 bottles a day by hand. They get tired, they spill, they weigh… With this machine, the same staff member can fill 3000-4000 bottles a day without getting tired. This increase in your production capacity allows the machine to pay for itself in a very short time.

In our view, a machine is not just a tool; it is a lever that determines the growth speed of your business. If you are a medium or small-scale enterprise, the way to play in the professional league without entering the massive costs of fully automatic lines is through these compact, semi-automatic heroes.

Conclusion: Take Your Production to the Next Level

In short, if you want to standardize quality in production, increase speed, and never compromise on hygiene, it’s time to say goodbye to manual filling methods. Kulp Machine’s semi-automatic filling solutions promise you not just a machine, but a trouble-free production process with the assurance of 316L stainless steel and user-friendly design.

You dream it, develop your formula; leave the filling business to us and our machines. Remember, every big brand once started in a small workshop with the right equipment. Now it’s your turn.

You can always contact us to discuss the most suitable solution for your business, to test your product, or simply to ask a technical detail. We look forward to having a coffee with you!

Frequently Asked Questions (FAQ)

1. Which products can I fill with a semi-automatic filling machine? These machines are quite flexible. You can fill a very wide range of products from water-like fluids to thick (viscous) products like honey, cream, gel, or tahini. The important thing is that the piston and nozzle structure of the machine is selected appropriately for your product.

2. Is cleaning the machine difficult? How long does it take to switch between different products? No, it is definitely not difficult. Kulp Machine products are designed with “tool-free” detachable parts. Thanks to its 316L stainless steel structure, it is easily washed. Switching from one product to another (for example, from honey to jam) takes an average of 15-20 minutes, including the cleaning process.

3. What is the filling accuracy? Is there a deviation in weights? Our machines work on the volumetric filling principle and are quite precise. Depending on the structure and homogeneity of the product, they generally operate with a very low tolerance, such as ±1%. This ensures you provide a standard product in every bottle.

4. Do I need technical personnel to use this machine? Absolutely not. Our semi-automatic machines are close to a “plug-and-play” logic. Your existing staff can use the machine professionally with a short training session provided by us.

5. What is the warranty and service status of the machine? At Kulp Machine, we stand behind every machine we produce. Our machines are under warranty, and even after the warranty period ends, we help you continue your production without interruption with our spare parts and technical service support. Being a local manufacturer, you won’t experience waiting issues regarding part supply.