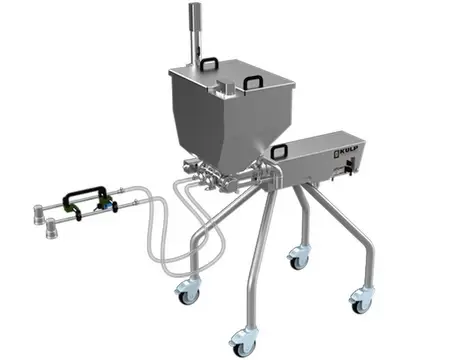

PASTRY FILLING MACHINE

Designed specifically for cake batter, sauces, creams, and similar products.

4-HEAD OEM FILLING MACHINE

NUMBER OF FILLING CYLINDERS ON THE MACHINE: 4 FILLING RANGE:

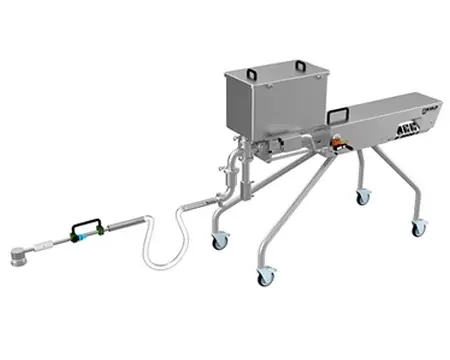

SINGLE HEAD OEM FILLING MACHINE

NUMBER OF FILLING CYLINDERS ON THE MACHINE: 1 FILLING RANGE:

CLOTTED CREAM FILLING MACHINE

NUMBER OF FILLING CYLINDERS ON THE MACHINE: 1 or 2

CLOTTED YOGURT FILLING MACHINE

NUMBER OF FILLING CYLINDERS ON THE MACHINE: 1 or 2

Special Design Filling Machines

Special Design Filling Machines: “Tailor-Made” Solutions Beyond the Standards

In the world of production, every product has a unique character, much like a fingerprint. Filling a standard shampoo or water is easy; you can find thousands of ready-made solutions for that. But what if your product is non-standard? What if you need to fit a filling unit into a very specific space in your existing packaging line, such as a thermoforming machine?

This is where the era of “selecting products from a catalog” ends and the art of engineering begins.

At Kulp Makine, we are not just machine manufacturers; we are solution partners. Sometimes with the precision of a pastry chef, sometimes with the hygiene obsession of a dairy specialist, and sometimes to meet the speed requirements of a massive packaging line, we sit down and design “from scratch.”

If standard machines are limiting your production dreams, you are in the right place. Let’s examine how Kulp Makine brings “impossible” projects to life, from OEM solutions to high-precision food filling.

Why Special Design? Because “One Size Does Not Fit All”

Think of the difference between buying a ready-to-wear suit and one custom-tailored for you by a master. Special design machines are the perfect outfit “stitched onto” your production line.

If you find yourself saying these sentences while looking for a machine, you need a special design:

“My product is very sensitive (e.g., clotted cream); its structure gets ruined when it enters the machine.”

“I have an existing packaging machine (thermoform); I need a filling unit that can be integrated into it.”

“I am in the pastry business; I need a robot that performs decorations like manual handwork.”

Kulp Makine’s R&D department listens to these needs and constructs a unique system just for you.

OEM Filling Groups: The Hidden Power Inside Machines

In the packaging sector, many companies produce tray sealing or thermoforming (vacuum forming) machines. However, the heart of these machines—the “filling” part—requires separate expertise. This is where we come in. Kulp Makine provides OEM (Original Equipment Manufacturer) filling groups to other machine manufacturers or facilities looking to add to their existing lines.

Single-Head and 4-Head OEM Filling Machines

Imagine you have a thermoforming line. Plastic trays are flowing as they are formed underneath. At that exact moment, the product needs to be filled into them without any pauses.

Single-Head OEM Systems: These are generally compact, high-precision units installed for lower capacity lines or at a specific point on the line (for example, to add sauce on top of a main course).

4-Head (or more) OEM Systems: Designed for high-speed lines. They fill 4 side-by-side trays simultaneously within milliseconds.

The greatest feature of these systems is their integration capability. Kulp Makine’s software communicates with the software of the main machine. It stops when told to “stop” and works synchronously when told to “fill.” No leaks, no timing errors.

Overcoming Tough Missions: Clotted Cream and Creamy Yogurt

One of the biggest tests in the food sector is “Clotted Cream” (Kaymak). Its structure is so fragile that if you attempt to transfer it with the wrong pump or pressure, that delicious texture is ruined, turning it into ordinary cream.

Creamy Yogurt Filling Machines

Consider our traditional delicacy, creamy yogurt. Yogurt at the bottom, with that pristine layer of clotted cream on top… Achieving this with a machine requires an engineering marvel. Kulp Makine’s special design nozzles and low-stress transfer pumps lay the cream onto the yogurt without “hurting” it. The product’s natural texture is preserved, and the consumer finds that handmade taste when they open the lid.

Clotted Cream Filling Machines

Filling clotted cream alone is also a separate art. Especially in applications like rolled clotted cream or cream toppings for pan yogurt, we use our special “Lobe” or “Piston” systems, modified specifically for the product, to preserve its fibrous structure.

Pastry Sector: Where Art and Technology Meet

In pastry, visuals are everything. The shape of the cream squeezed onto a cake, the amount of filling inside an éclair… Pastry Filling and Decoration Machines are among Kulp Makine’s most colorful solutions.

Dosing Precision: If you squeeze too much cream into an éclair, it bursts; if you squeeze too little, the customer is unhappy. Our machines fill gram for gram.

Decoration: Thanks to special tips, we can pour cream or sauces onto cakes in aesthetic forms as if they were squeezed by hand.

Hot/Cold Application: We design jacketed (heated) hoppers for products that need to be kept hot (at a specific temperature), such as chocolate sauce.

How Does the Process Work? From Idea to Factory

A special design machine process is different from a standard sale. It is a journey.

Analysis: We listen to you. We understand your product, your factory layout, your speed goals, and most importantly, your “dream workflow.”

Design and Simulation: Our engineers design the machine in a 3D environment. Before a single screw is tightened, you see how the machine will work in simulations.

Production and Software: The 316L stainless steel body is processed, and the electronic brain (PLC) is coded. Your specific recipes are uploaded to the system.

FAT (Factory Acceptance Test): When the machine is finished, you conduct trials with your own product in our factory. Fine-tuning continues until you say, “Yes, exactly what I wanted.”

The Human Touch: For Us, “Impossible” is Just a Challenge

As Kulp Makine, the projects that excite us the most are those where a customer walks through the door and starts with, “We couldn’t find a machine that could do this; everyone said it’s impossible.” Our passion for engineering kicks in at that “impossible” point. Filling clotted cream without ruining its texture or fitting 4 heads into a millimetric space… These are not just jobs for us; they are puzzles. And we love solving puzzles.

Conclusion: Your Product, Your Machine

If you want to differentiate yourself from your competitors, do not be afraid to step outside the standards. With Kulp Makine’s special design solutions, fit your production line to your product; do not compromise on quality by trying to fit your product to a standard line.

From OEM filling groups to sensitive dairy products, from boutique pastry to industrial solutions—whatever you have in mind, we have the technology to bring it to life. Let’s talk about your project over a cup of coffee. You’ll be surprised at what we can design for you.

Frequently Asked Questions (FAQ)

1. Is a special design machine very expensive?

“Expensive” is a relative term. Yes, the initial investment cost may be slightly higher than a standard machine because of the significant R&D and engineering hours involved. However, the return on investment (ROI) of a machine that perfectly meets your needs, prevents waste, and saves on labor is much shorter than a poorly chosen cheap standard machine.

2. How long does the delivery take?

While we can deliver standard machines from stock or in a short time, special design projects can take between 8 to 16 weeks depending on the complexity. This period covers design, manufacturing, and detailed testing phases.

3. How do I connect the OEM filling group to my existing packaging machine?

Kulp Makine’s OEM units are designed close to the “Plug & Play” logic. They come with their own electrical panel and PLC but operate with a simple “signal” (dry contact) from your main machine. Our technical team ensures seamless integration by communicating with the manufacturer of your existing line.

4. What happens if the product structure is ruined during clotted cream filling?

This is our area of expertise. Before delivering the machine, we conduct tests in our factory with your original product. We do not ship the machine until you approve the consistency, taste, and appearance of the resulting product. You take no risks.

5. Will I have spare part problems in the future?

No. Even if it is a special design, the components we use (motors, sensors, pneumatics) are world-renowned, universally available brands (Festo, Siemens, Omron, etc.). The projects for mechanical parts are kept in our digital archive; even if you request a part 10 years later, we can reproduce it for you.